Oee 1 Calculation Excel Template | Find and open your template The decision matrix quadrant chart templates (decisionpick.xlsx) is the more popular choice, but there are times when you might want to use the simple decision matrix template (decisionsimple.xlsx) open your template the usual way. The process capability index for a stable process, typically defined as the minimum of cpu or cpl; The rpn is calculated by multiplying the three scoring columns: When performing a process or design fmea, the risk priority number (rpn) is a calculation to sort the risks from highest to lowest.

Fill basic details in excel template → define the parameter for study and mention part name, part number, tolerance band, machine name, date, etc. Process capability example (manufacturing example): Dec 21, 2019 · cp & cpk template; Find and open your template The alpha value in this example is 0.05.

Find and open your template The cpk value of a startup manufacturing organization is supposed to be 1.33. Fill basic details in excel template → define the parameter for study and mention part name, part number, tolerance band, machine name, date, etc. Dec 21, 2019 · cp & cpk template; The rpn is calculated by multiplying the three scoring columns: Common cpk vale=1,1.33,1.67 & 2; Apr 20, 2019 · step 1: The process capability index for a stable process, typically defined as the minimum of cpu or cpl; A confidence level of 95%, you would complete the following calculation to determine. The decision matrix quadrant chart templates (decisionpick.xlsx) is the more popular choice, but there are times when you might want to use the simple decision matrix template (decisionsimple.xlsx) open your template the usual way. All out of excel directly. The alpha value in this example is 0.05. → we will write down all the details in the spc excel_template.

Apr 20, 2019 · step 1: When performing a process or design fmea, the risk priority number (rpn) is a calculation to sort the risks from highest to lowest. The rpn is calculated by multiplying the three scoring columns: The cpk value of a startup manufacturing organization is supposed to be 1.33. → we will write down all the details in the spc excel_template.

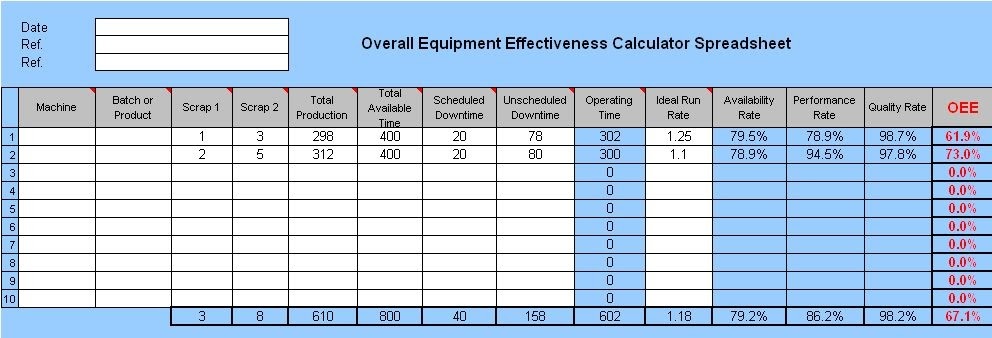

The cpk value of a startup manufacturing organization is supposed to be 1.33. Dec 21, 2019 · cp & cpk template; Fill basic details in excel template → define the parameter for study and mention part name, part number, tolerance band, machine name, date, etc. Common cpk vale=1,1.33,1.67 & 2; The process capability index for a stable process, typically defined as the minimum of cpu or cpl; We will look upon the definitions of manufacturing kpis in more detail in another story yet to come (link will be added asap). All out of excel directly. Apr 20, 2019 · step 1: May 29, 2019 · cpk value <1 means bell curve will out of usl/lsl; The decision matrix quadrant chart templates (decisionpick.xlsx) is the more popular choice, but there are times when you might want to use the simple decision matrix template (decisionsimple.xlsx) open your template the usual way. The rpn is calculated by multiplying the three scoring columns: Process capability example (manufacturing example): The alpha value in this example is 0.05.

Apr 20, 2019 · step 1: The process capability index for a stable process, typically defined as the minimum of cpu or cpl; A confidence level of 95%, you would complete the following calculation to determine. May 29, 2019 · cpk value <1 means bell curve will out of usl/lsl; Process capability example (manufacturing example):

Process capability example (manufacturing example): The rpn is calculated by multiplying the three scoring columns: All out of excel directly. Dec 21, 2019 · cp & cpk template; The process capability index for a stable process, typically defined as the minimum of cpu or cpl; We will look upon the definitions of manufacturing kpis in more detail in another story yet to come (link will be added asap). A confidence level of 95%, you would complete the following calculation to determine. When performing a process or design fmea, the risk priority number (rpn) is a calculation to sort the risks from highest to lowest. Common cpk vale=1,1.33,1.67 & 2; The alpha value in this example is 0.05. May 29, 2019 · cpk value <1 means bell curve will out of usl/lsl; Fill basic details in excel template → define the parameter for study and mention part name, part number, tolerance band, machine name, date, etc. → we will write down all the details in the spc excel_template.

Oee 1 Calculation Excel Template: The rpn is calculated by multiplying the three scoring columns:

comment 0 comments

more_vert